We've all been here, red faces flagging up all over our models thwarting our attempts to produce consistently printable models. Just to emphasize how annoying this can get, here is a screenshot of my

Caswell Flats STL just after export from Google Sketchup:

|

| Just you wait until you introduce curves into the model... |

See those red areas? Those are degenerate faces, and they can do much more besides making the model unsightly, up to and including causing a non-manifold model - all 3D printers require the model to be "watertight" or manifold to print, that means there must be one consistent shell.

Having gained much practice in handling STL files, usually through frustration, I thought I'd put it to use by outlining these three tips to flush out the degenerates and, better yet, prevent them from happening in the first place:

1. Get Netfabb

Let's face it, computers being computers, no CAD program is ever going to produce a perfectly error-free *and* a detailed, high-resolution model first time (even if such a program did exist, the cost would be horrendous); enter

Netfabb - a slick, attractive application that makes light work of banishing the reds. The Basic version is free to download and use with no time limits, and it fixes most errors with automatic ease; it is, however, limited to the most basic of STL sins and cannot, for instance, Wrap Part Surface which reconstructs the shell of a model to close up the holes. For £200 you can upgrade to Netfabb Private, which allows access to all the tools you'll ever need to fix STLs (I personally cannot comment on their effectiveness since I only use basic, still, one for the future investments list). There is a hideously-priced Professional version costing 1500 Euros, which I'd only suggest if an automatic nesting algorithm sounds vital to you.

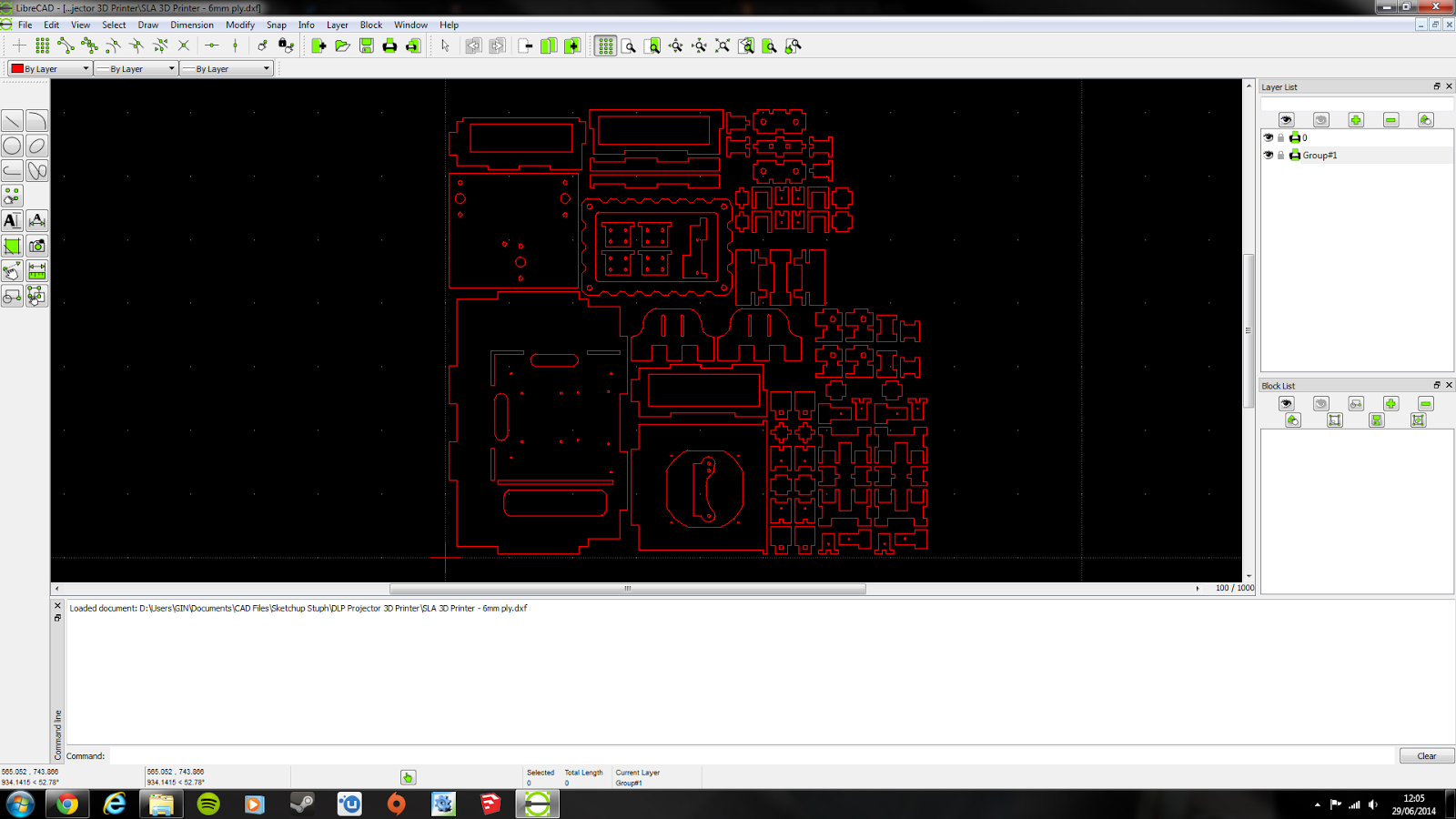

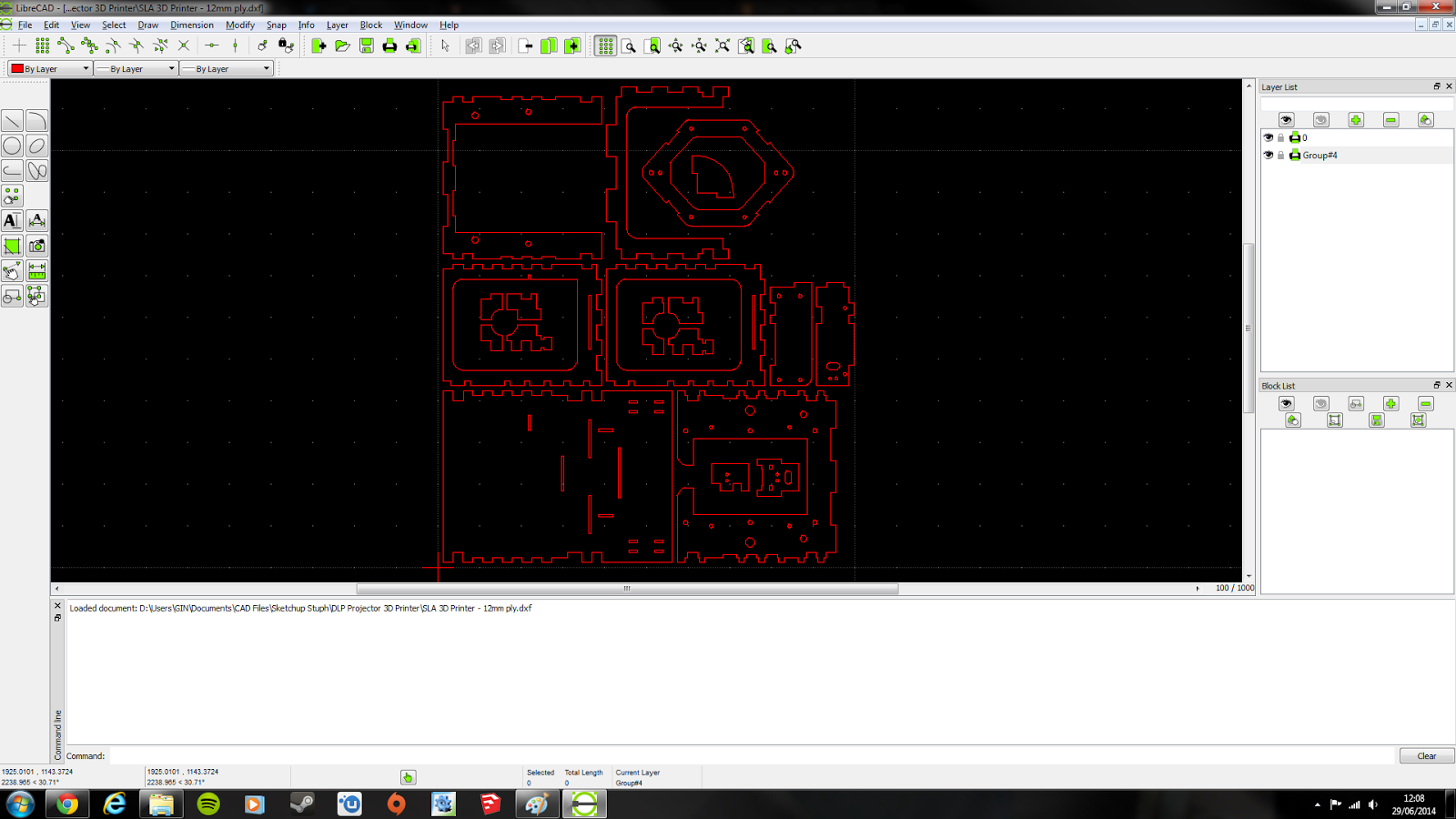

2. Reduce the resolution of your models before exporting to STL

Not a sure-fire fix, but one that can get your models from 'RED ALERT!' to 'that'll do'. Resolution pops up in many different ways, for instance

Creo Elements Direct (which I strongly suggest you get if you want to model curves) features an 'Facet Accuracy' setting, accessed via Right-Clicking the Part, selecting Part Properties, then the Facets tab; This will give the option to set either the minimum distance or angle the model will be permitted to render. This is the result if I go for the insane resolution of 0.5 degrees:

|

| Aside from bringing my new AMD R9 290 Graphics Card to it's knees, this is what 5244010 triangles and 250mb of Chassis looks like. |

So you're thinking it's not too bad, except that 73 shells and 144 holes are produced... Netfabb ran out of memory trying to fix it (silence...).

Let's go down a gear to 1 Degree and see how it is:

|

| Errors around the Pinpoint bearing holes are reduced :) |

The repair I tried in Netfabb Basic did little if anything to reduce those lines, although this exercise illustrates a point: Reducing the resolution not only rids you of reds, but it also reduces strain on your Graphics Card as it renders the model and it makes smaller files with the 1 Degree file being 67.6mb.

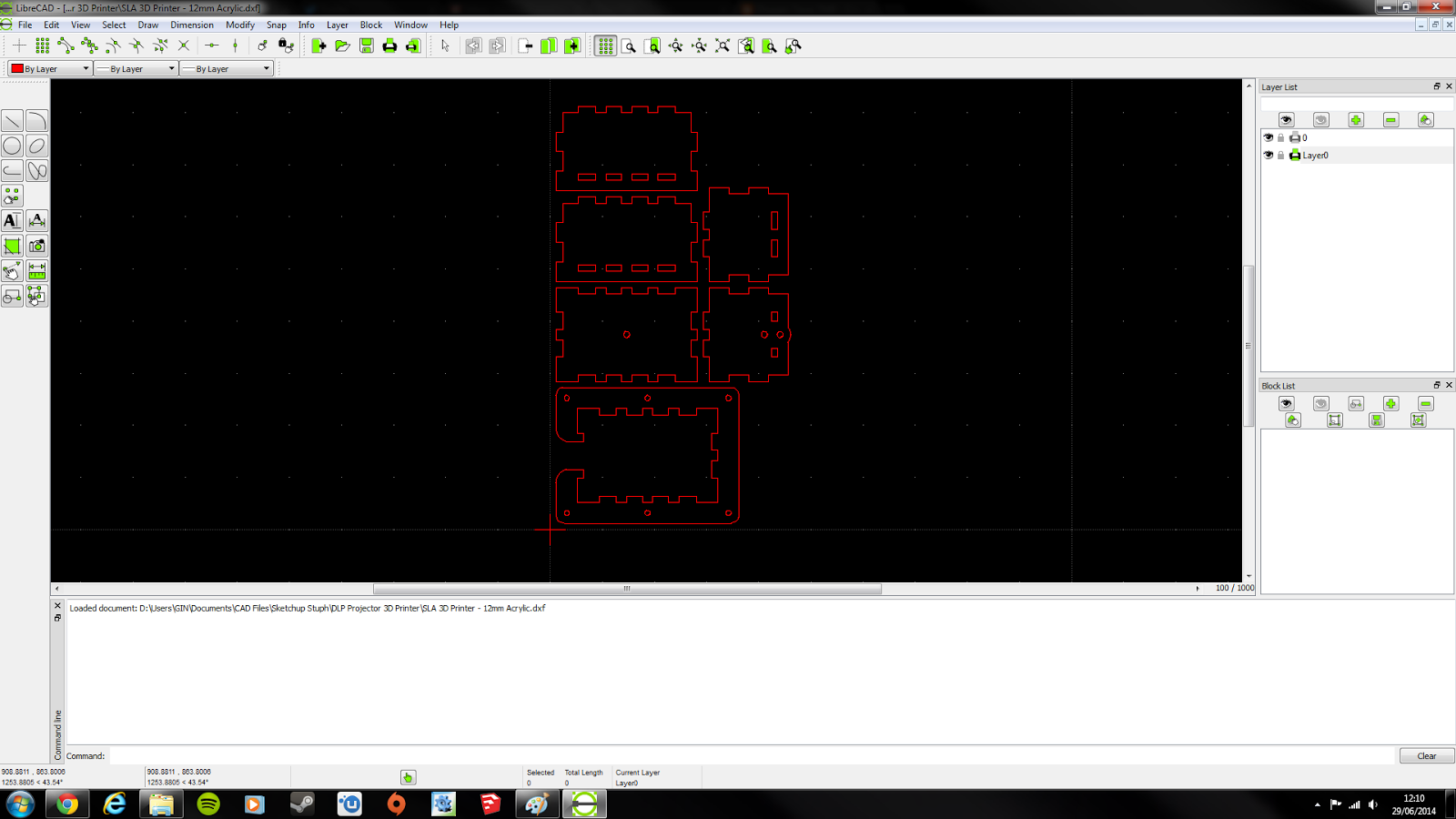

3. (Sketchup Users) Use Solid Inspector

Sketchup hit the spot for many modellers when it introduced it's extension warehouse, myself included - trawling the internet for obscure, often poorly-optimized plugins is now banished to the past along with floppy disks and those chirpy modem things. One of these plugins to come to our rescue is Solid Inspector, a straightforward function which highlights any issues with Sketchup models by circling surplus lines with orange and holes with red:

|

| This is a rather severe example, but you can hardly blame us when you take the Tumblehome into account. |

That was the body of No. 394 of the Chesham set of Metropolitan Bogie Carriages, at which me and

Matt Wickham at Bluebell Model Railway (click here for some video of the carriages running) have been beavering away on for some time; Admittedly finding the actual rogue lines and holes is still tricky since the circles don't always scale to your viewport, but as a general indicator it's a godsend which can mean the difference between printing and self-inflicted pain.

The Takeaway: 3D Printing, not 3D Perplexity

There may well be other methods I have failed to mention, but I can sum this post up thus: Don't rely on your eyes to find faults. A CAD model, unlike your hands, CNC machines and even reality, can scale down into infinitude, theoretically to the Planck Length and below; that said, god help you if you want to zoom back out again!

.JPG)

.JPG)

.JPG)

.JPG)